Good to see you

Welcome to Dulux Trade

Terms and Conditions

Thanks! for registering

Successfully registered, please login

Registration complete

Forgotten your password?

Please enter email address associated to your account

Change Password

Password changed successfully.

Request sent!

Would you spare a minute to answer 3 questions

Registration complete

Successfully registered, please login

Delete Account

Sikkens Cetol HLS

-

Highly translucent to bring out the beauty of woodgrain

-

Protects against mould and algae

-

Resistance to UV radiation, peeling and cracking

-

Microporous and water-repellent

-

Finish Semi-gloss

-

Coverage 7-14 m²/L

-

Drying Time 4-6 hours

-

Recoatable 18-24 hours

-

Composition Solvent-based

-

UV Resistant

Product Description

Application Description

application or drying periods. Protect from frost and rain until dry.Failure to meet these requirements may adversely affect the drying, visual quality and durability of the finish.Initial Procedure Ensure product is thoroughly stirred before and during application, otherwise sheen and colour variations may be experienced.

Cetol HLS plus is supplied ready for use. Do not thin.Applying the product For best results use a good quality, long-haired, soft bristle brush. On new work, where practical, the initial coat should be

applied all round prior to fixing. P ay special attention to any areas of exposed end grain, tops and bottoms of doors, and

undersides of cills.The product should be applied in a full flowing coat (working well into joints, and ensuring end grains or sawn timbers are saturated with product). Excess surface material should be re-distributed after 5-20 minutes (depending on conditions), using a dry brush (which should be periodically dried with a lint-free cloth) and the minimum number of strokes required to produce an even overall colour. This ensures that the first coat satisfies the porosity/absorption of the timber.

Allow a minimum of 18-24 hours drying time. Where appropriate (e.g. for joinery items such as windows and doors), the first

coat should be carefully denibbed using a fine grade nylon abrasive pad or a fine grade (P240 or finer) wet or dry silicon carbide abrasive paper, in the direction of the grain. Do not break through the surface coating. Remove all dust.Cetol HLS plus should be applied in a full flowing manner in the direction of the grain, using the minimum number of brush strokes necessary to produce an acceptable finish. Avoid overbrushing, as this will reduce the protection afforded.Subsequent coatings should be applied as soon as possible after the previous coat has dried, but no sooner than 12-24 hours, in order to provide full protection. In any event this period should not extend beyond three months, otherwise additional preparation and coats may be necessary. If applied to exterior timber and the contract is of long duration, it is suggested that a further coat be applied prior to handover to make good any weathering during the construction period

Technical & Safety Documentation

Tips & Advice

-

1. Preparing the SurfacesGeneral: Ensure the timber surface is suitably prepared, clean and dry, with dust, dirt, wax atnd grease removed and allowed to acclimatise to its end-use environment. The moisture content should not exceed 18% prior to coating.Degrease any exposed bare timber surface by wiping with a cloth dampened in a suitable solvent. Certain timber species contain

high levels of natural wood extractives or exudates and some softwood can be highly resinous. Resinous deposits should be removed with a scraper. Any remaining residues should be removed using a lint-free cloth dampened with a suitable solvent, frequently changing the face of the cloth. Allow solvent to evaporate fully before overcoating. The use of both eye and hand protection is strongly advised.

We do not recommend the use of “knotting agents” with translucent finishes as they are not always fully effective in “sealing in” resin,the presence of knots is often highlighted and adhesion of coatings can be impaired.When filling, be sure to use fillers specifically designed for use with timber. General or all purpose fillers are not suitable, particularly on external areas, as they cannot cope with timber movement and work loose.

New timber: Where a superficial application of preservative to softwood and hardwood is deemed necessary, such as timbers in Durability Class

3 or lower, use Cuprinol Wood Preserver Clear (BP). For Class 4 (in ground contact) and 5 (marine), use pre-treated wood specific for these conditions. Preservative pre-treatments must be fully dry before the application of Cetol HLS plus. Do not use on substrates which have had water-repellent preservative pre-treatments applied. Where possible, the first coat should be applied all round prior to fixing. Only use non-ferrous screws, nails and fixings.Base stained / Primed : Denib using a fine grade nylon abrasive pad or a fine grade (P240 or finer) wet or dry silicon carbide abrasive paper, in the direction of the grain. Do not break through the surface coating. Remove all dust.

To ensure optimum durability and uniformity of appearance, we recommend the use of a coat of Cetol HLS plus prior to finishing.

Note: Where there is localised damage, or deterioration has occurred as a result of exposure of the factory coating for longer than 3 months, affected areas should be thoroughly sanded back to a sound substrate.

All damaged or decayed timber must be removed and replaced, cutting at least 25mm into sound timber. When splicing in new sections of timber, consideration should be given to the use of a timber species whose natural durability is sufficient. Brush apply two coats of Cuprinol Wood Preserver Clear (BP) to saturation. Ensure timbers are thoroughly treated, especially any end grain sections, and are fully dry before splicing in. Secure with non-ferrous fixings and fill all voids surrounding the spliced-in area with a suitable repair compound such as Dry-Flex from Repair Care -

2. After useCleaning After Final Use- Clean brushes and rollers immediately after final use to reuse them for future projects, saving you money and reducing waste. Cleaning Steps- 1. Remove Excess Product- Scrape off leftover product into a container for reuse. 2. Use Brush Cleaner- Use a Brush Cleaner to clean brushes and rollers. 3. Reuse Brush Cleaner- Allow the paint solids to settle and reuse the cleaner by pouring the clear liquid into another container. 4. Dry Naturally- Let tools air-dry and store in a dry, dust-free area. Dispose Responsibly- Dispose of the remaining solids and used brush cleaner at a hazardous waste facility. Do not pour any solvent-based paint, brush cleaner or washings down the drain or onto the ground. Do not flush paint down the drain, including when cleaning painting tools

-

3. StoringStoring & Responsible Disposal Do not use or store in extreme temperatures and protect from frost. Whenever possible, reuse, recycle, or donate leftover paint. Find local services at recyclenow.com. If no Community RePaint service is nearby, consider advertising paint locally—many good causes need it to brighten community spaces. Dispose Responsibly- Never pour paint or waste washings down drains or sinks. Follow instructions at recyclenow.com to recycle empty packs. Reuse Roller Cages- Remove sleeves and store cages in a dry, dust-free place. If brushes or sleeves cannot be cleaned or reused, dispose of them in general waste to avoid recycling issues. Paint Washings- Collect used brush cleaner in a container; don't pour it into drains or on the ground. Let solids settle, pour off clear liquid into another container for reuse or disposal. Dispose of remaining solids and used cleaner at a hazardous waste facility. Do not flush paint down drains, including when cleaning tools.

How much paint do I need?

More than one wall to paint? Try our advanced paint calculator

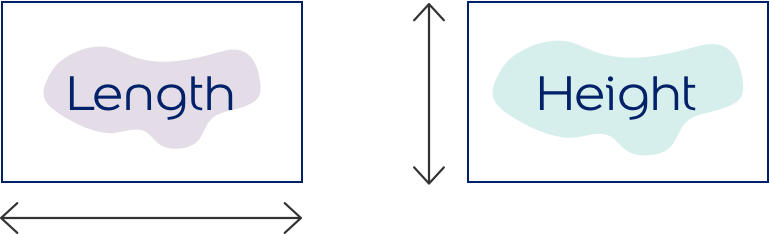

Measure the height and length of the surface you want to paint (in metres or centimetres).

Your Measurements:

{{!-- This value will be injected with JavaScript --}}

Amount needed:

{{!-- This value will be injected with JavaScript --}}

Actual coverage will depend on the conditions of the surface. If the colour change is strong, more coats may be required.

Add a new job

Add a new job

Edit job

Delete job

Are you sure? All notes, photos and saved items will be deleted.

Save Color

Save to My Workspace

Add to job

Sikkens Cetol HLS

Save to My Workspace