Good to see you

Welcome to Dulux Trade

Terms and Conditions

Thanks! for registering

Successfully registered, please login

Registration complete

Forgotten your password?

Please enter email address associated to your account

Change Password

Password changed successfully.

Request sent!

Would you spare a minute to answer 3 questions

Registration complete

Successfully registered, please login

Delete Account

Sikkens Cetol BL Unitop

-

Excellent resistance to knocks, spillages and abrasion

-

Non-yellowing

-

Low odour

-

Quick drying

-

Finish Satin

-

Coverage 12-18 m²/L

-

Drying Time 2 hours

-

Recoatable 5 hours

-

Composition Water-based

-

Durable

Product Description

Application Description

For best results use a good quality synthetic-fibre brush specifically designed for the application of water-borne products. Apply the product in a full flowing coat, laying off in the direction of the grain, using the minimum number of brushstrokes

required to produce an even finish. Avoid overbrushing, which creates brushmarks and will reduce the protection afforded.

This initial coat should satisfy the porosity/absorption of the timber. Carefully denib the first coat using a fine grade nylon abrasive pad or a fine grade (P240 or finer) wet or dry silicon carbide abrasive paper. Remove all dust. Three coats of Cetol BL Decor should be applied, allowing a minimum of 5 hours drying time between coats or a two coat application onto a coloured coating such as Cetol BL Decor for protection.

Technical & Safety Documentation

Tips & Advice

-

1. Preparing the SurfacesEnsure the timber surface is suitably prepared, clean and dry, with dust, dirt, wax and grease removed, and allowed to acclimatise to its end-use environment. The moisture content should not exceed 14% prior to coating. We do not recommend the use of “knotting agents” as they are not always fully effective in “sealing in” resin. In addition, the

presence of knots is often highlighted, and adhesion of coatings can be impaired.

When filling, be sure to use fillers specifically designed for use with timber. General or all-purpose fillers are not suitable,particularly on external areas, as they cannot cope with timber movement and work loose. Only use non-rusting screws, nails and fixings.New timber : Degrease any exposed bare timber surface by wiping with a cloth dampened with a suitable solvent. Certain timber species contain high levels of natural wood extractives or exudates and some softwood can be highly resinous. Resinous deposits should be removed with a scraper. Any remaining residues should be removed using a lint-free cloth dampened with suitablesolvent, frequently changing the face of the cloth. Allow solvent to evaporate fully before overcoating. The use of both eye and hand protection is strongly advised.All damaged or decayed timber must be removed and replaced, cutting at least 25mm into sound timber. Secure any new spliced-in timber with non-ferrous fixings and fill all voids surrounding the spliced-in area with a suitable repair compound such as Dry-Flex from Repair Care. -

2. After useCleaning After Final Use: Clean brushes and rollers immediately after final use to reuse them for future projects, saving you money and reducing waste. Cleaning Steps: 1. Remove Excess Product: Scrape off leftover product into a container for reuse. 2. Wash with Warm, Soapy Water: Clean brushes and rollers with warm soapy water in a sealed container like a bucket or tub. 3. Rinse Thoroughly: Rinse out all soap and product residues into the same container. 4. Dry Naturally: Let tools air-dry and store in a dry, dust-free area. Dispose Responsibly: Settle Solids: Let solids settle at the bottom of the container. Pour off clear water for reuse or disposal. Disposal: Let remaining solids dry fully before disposing of them as solid waste. Do not flush paint down the drain, including when cleaning painting tools Pro Tip: Watch this cleaning guide from the British Coatings Federation and Dulux Connect contractor Bagnall’s: https://coatings.org.uk/general/custom.asp?page=HowToCleanPaintbrushes

-

3. StoringStoring & Responsible Disposal Do not use or store in extreme temperatures and protect from damp & frost. Reuse, Recycle, or Donate- Whenever possible, reuse, recycle, or donate leftover paint. Find local services at recyclenow.com. If no Community RePaint service is nearby, consider advertising paint locally—many good causes need it to brighten community spaces. Dispose Responsibly- Never pour paint or wastewater down drains or sinks. Follow instructions at recyclenow.com to recycle empty packs. Reuse Roller Cages- Remove sleeves and store cages in a dry, dust-free place. Dispose of Unusable brushes and Sleeves- If brushes or sleeves cannot be cleaned or reused, dispose of them in general waste to avoid recycling issues. Paint Wash Water- Collect wash water in a container; don’t pour it into drains or on the ground. Let solids settle, pour off clear water for reuse or disposal, and let solids dry before disposing as solid waste. Do not flush paint down drains, including when cleaning tools.

How much paint do I need?

More than one wall to paint? Try our advanced paint calculator

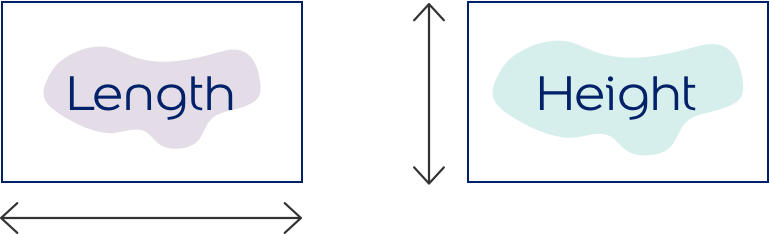

Measure the height and length of the surface you want to paint (in metres or centimetres).

Your Measurements:

{{!-- This value will be injected with JavaScript --}}

Amount needed:

{{!-- This value will be injected with JavaScript --}}

Actual coverage will depend on the conditions of the surface. If the colour change is strong, more coats may be required.

Add a new job

Add a new job

Edit job

Delete job

Are you sure? All notes, photos and saved items will be deleted.

Save Color

Save to My Workspace

Add to job

Sikkens Cetol BL Unitop

Save to My Workspace